Uncompromising Accuracy with Industry-Leading Metrology

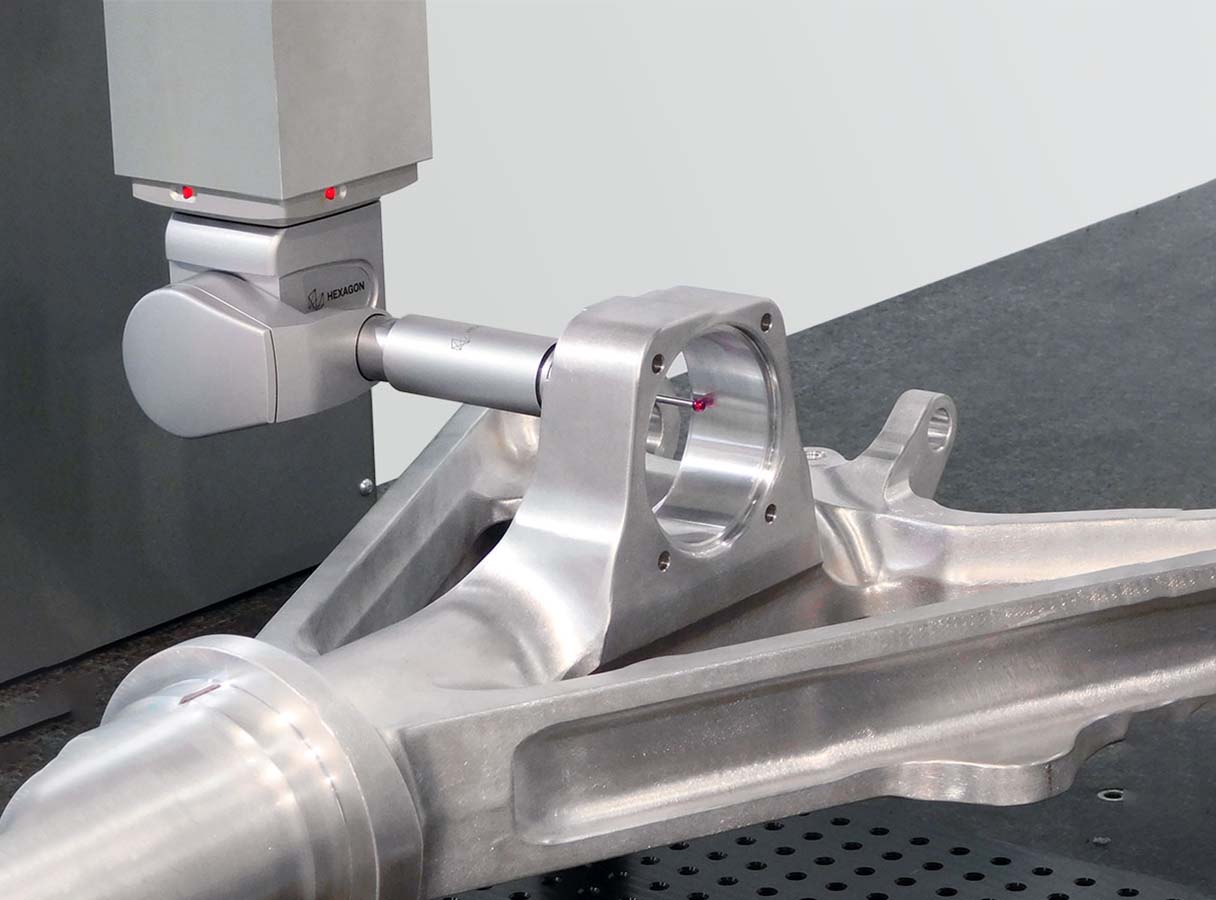

In 2026, precision is defined by the data behind every part. To guarantee the absolute integrity of your mission-critical components, our inspection department utilizes the Hexagon Global Scan+ Coordinate Measuring Machine (CMM).

This world-class platform provides high-speed, sub-micron accuracy for the most complex 5-axis geometries, ensuring that every dimension adheres strictly to your engineering specifications.

By leveraging advanced scanning technology, we move beyond simple point-to-point measurement to capture thousands of data points per second, allowing us to identify even the most minute deviations in form and profile before your parts ever leave our facility.

Versatile, Real-Time Verification with 7-Axis Laser Scanning

For components requiring rapid, high-definition inspection or complex on-machine verification, we deploy the Hexagon Absolute Arm with the 7-Axis AS1 Scanner. This cutting-edge portable metrology solution allows our technicians to perform non-contact 3D laser scanning with unparalleled flexibility.

The 7-axis movement of the arm provides effortless access to deep recesses and obscured features that traditional tools miss. Whether we are conducting first-article inspections or reverse-engineering intricate aerospace assemblies, the AS1 Scanner delivers real-time, high-density point clouds that validate part quality against CAD models with total transparency.

When you partner with us, you aren't just getting machined parts—you are getting documented excellence backed by gold-standard inspection technology.

Uncompromising Excellence in Every Dimension

From mission-critical defense components and high-performance aerospace structures to complex commercial assemblies, we deliver precision that exceeds 2026’s most rigorous industry benchmarks. Our facility integrates advanced 5-axis CNC machining with a dedicated assembly department, providing a seamless transition from raw material to flight-ready systems. By centralizing these processes under one roof, we ensure total design integrity, absolute traceability, and reduced lead times for even the most intricate engineering challenges.

Our commitment to quality is anchored by a world-class metrology suite featuring the Hexagon Global Scan+ CMM for sub-micron accuracy and the Hexagon Absolute Arm with the 7-Axis AS1 Scanner for versatile, high-speed 3D laser verification. This dual-layer inspection strategy allows us to capture high-density data points and perform real-time CAD-to-part comparisons, guaranteeing that every component meets exacting tolerances. Backed by a culture of compliance—including ITAR registration and adherence to AS9100 standards—we provide the tactical reliability and documented excellence required for the future of global manufacturing.

CAGE CODE: 0NAP8

UEI: NN75TNQACFU5

Copyright 2026 - All Rights Reserved. | Site Powered by Sunken Treasure Design